- © Philadelphia in the World War, 1914-1919 (Philadelphia War History Committee, 1922), pp. 444-446. By permission of William Bradford Williams.

FAYETTE R. PLUMB, INC. Manufacturers of trench tools, Bolo knives, etc.

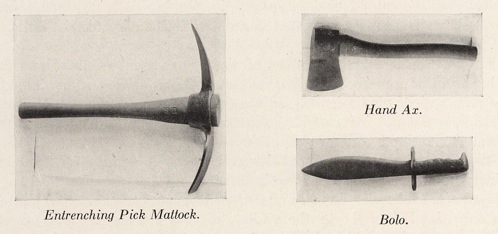

An instance showing the way in which Philadelphia factories made a quick turn-over from a peace to a war basis is that of the plant of Fayette R. Plumb, Inc., at Bridesburg, which firm, for over sixty years, had been manufacturing hammers, hatchets, picks, sledges and axes. While all of these were required for the American Army, there were other articles of which the Government stood in more vital need. These the Plumb Company were able to manufacture by making certain changes in their plant, and as the result of experience in the manufacture of certain trench tools, etc., for the Allied governments, during the period of 1914-17.

Within two months after the declaration of war by the United States, intrenching pick mattocks and intrenching hand axes were shipped to mobilization points, both for the artillery and the infantry. This knife had been evolved from the old Philippine bolo, and in France it proved to be not only a very handy camp and trench tool but also a very effective weapon of defense. During the summer of 1917, the Plumb concern was ordered to make 20,000 bolos of the artillery model. While these were being manufactured, changes in design suggested themselves that would lower the manufacturing cost and speed up production. One of the principal defects of the old model bolo was the catch which was used for locking it in its scabbard. This catch was not only difficult to make but it proved very impractical in use, and it was later eliminated from the bolo itself and a spring was placed in the scabbard which solved the difficulty. This was called the 1917 bolo. All of these changes, suggested by the Plumb engineers, were worked out by the engineering staff of the Ordnance Department, which, making actual tests in the field, could decide in a few days whether or not the changes were practical.

While the Plumb concern was furnishing bolos as fast as the Government required them, the Ordnance Department was experiencing considerable difficulty in obtaining a satisfactory scabbard for them. A bolo scabbard is a sheath fastened to the soldier's belt and made of wood and leather with a metal mouthpiece. The wood and leather parts of the scabbard could be easily obtained, but the metal mouthpiece had to be made with precision in order that the bolo would fit snugly and not rattle. The success of the Plumb concern in turning out in volume bolos made to close measurements resulted in orders for the metal mouthpieces, 121,000 of which were furnished by Plumb before other manufacturers were ready to take over this work.

Production of intrenching picks and camp axes had also been speeded up and the monthly production of these items in November, 1918, was 40,000 of the picks and 45,000 of the hand axes. This volume of tools was obtained with only a 70 per cent increase in the working force, and of this increase approximately 50 per cent were women. Such work as drop forging, the drop hammers giving 1,500-pound blow, and working on a furnace with a heat of 1,400 degrees Fahrenheit, are examples of the work that was done by women during the latter part of the war.

Among other problems given to the Engineering Division of the Ordnance Department to solve was that of wire-cutters. It developed early in the war that when our troops advanced under cover of darkness and attempted to cut the German wires they had invariably to turn back and let the artillery open the way, as the wire-cutters with which they were equipped would either break or the edges would turn and dull. Samples of the German wire were obtained and found to contain an alloy which made it harder and tougher than any of the wire-cutters that the Allies used. A wire-cutter was developed over there in the field and sent to America to be reproduced in quantity. Manufacturers who had been making wire-cutters rejected this new model as being too difficult to produce from a commercial standpoint. Again the Ordnance Department turned to the Plumb Company and placed the proposition before them. It was accepted and complete wire-cutters exactly like the model were ready for shipment to France when the armistice came.

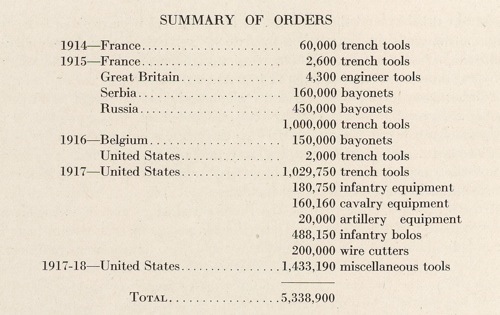

From 1914 to 1918 the Plumb plants turned out considerably over 5,000,000 different tools directly for the Allied governments, this quantity being over and above any of the articles which they regularly manufactured and which later found their way to the battle front of Europe. The following list shows not only the volume, but also the diversity of the items manufactured: